Why American Manufacturing Is the Best Way To Source Wiring Harnesses

When it comes to sourcing wiring harnesses, American manufacturing stands out as the best choice. With a rich history of producing high-quality products, American manufacturers offer a multitude of benefits that can give businesses a competitive edge. In this blog, we'll explore the reasons why American manufacturing is the preferred option for sourcing wiring harnesses.

Quality

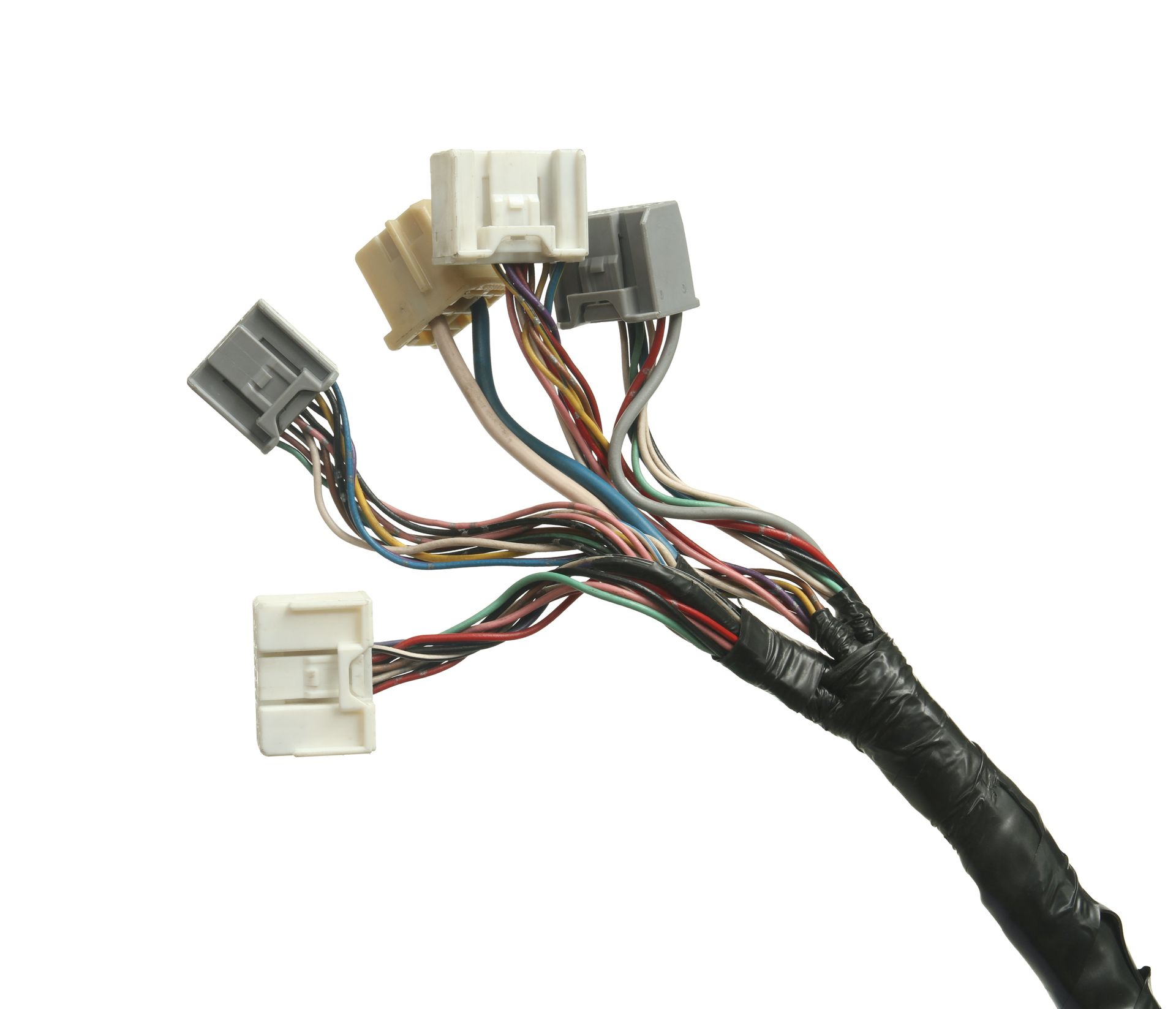

American manufacturers have built a reputation for delivering superior quality wiring harnesses. They employ cutting-edge technology and utilize premium materials to ensure that their products meet the highest industry standards. This commitment to quality is particularly crucial for businesses that prioritize reliability and safety. By sourcing from American manufacturers, businesses can have confidence in the durability and performance of their wiring harnesses, enhancing their brand reputation and customer satisfaction.

Speed

In today's fast-paced market, speed is a significant factor in business success. American manufacturers excel in meeting customer demands quickly and efficiently. With streamlined processes and the ability to rapidly scale up production, they ensure that businesses can get their products to market swiftly. This agility helps companies avoid stockouts and delays, enabling them to seize opportunities, satisfy customers, and maintain a competitive edge.

Flexibility

Flexibility is a key attribute of American manufacturers that sets them apart from their competitors. With the ability to adapt rapidly to changing customer demands, they offer businesses the necessary agility to navigate dynamic markets. American manufacturers can quickly reconfigure their production lines to accommodate new products or changes in demand. This responsiveness allows businesses to stay ahead of the competition, meet customer needs, and explore new opportunities without compromising on efficiency or quality.

Cost

Cost-effectiveness is a significant advantage offered by American manufacturers. They can produce wiring harnesses at a competitive cost without compromising on quality. This advantage is attributed to factors such as the availability of skilled labor, efficient production methods, and close proximity to major markets. By sourcing from American manufacturers, businesses can achieve cost savings while maintaining the desired level of quality, ultimately enhancing their profitability and financial stability.

Support

American manufacturers understand the importance of providing comprehensive support to their customers. They offer a range of support services, including technical assistance, training programs, and warranty support. This commitment to customer satisfaction ensures that businesses can optimize the performance of their wiring harnesses and address any potential issues promptly. The availability of reliable support further strengthens the partnership between businesses and American manufacturers, fostering long-term success and collaborative growth.

There is still a level of pride connected to the words "Made in America". American manufacturing stands out as the optimal choice for sourcing wiring harnesses. With an unwavering commitment to quality, remarkable speed, exceptional flexibility, cost-effectiveness, and comprehensive support, American manufacturers offer a compelling value proposition to businesses of all sizes. By choosing domestic manufacturing, businesses can access superior wiring harnesses that meet their unique requirements while driving efficiency, reliability, and success.

Proudly Manufactured in the United States

At RPI, we take great pride in manufacturing custom wiring harnesses that are made right here in the US. From our base in Racine, Wisconsin, we use only the highest quality materials and components to craft wiring solutions that are durable, reliable, and built to last. By choosing RPI, you can trust that you are getting a product that is not only tailored to your specific needs, but also represents the quality and craftsmanship of American manufacturing.

Upload Your Design

Build Spec Review of your Design Guided by a Dedicated Program Manager

Design Review by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

Start Your Design

Design and Development Process with a Dedicated Program Manager

Design Drawings performed by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

More Recent Insights