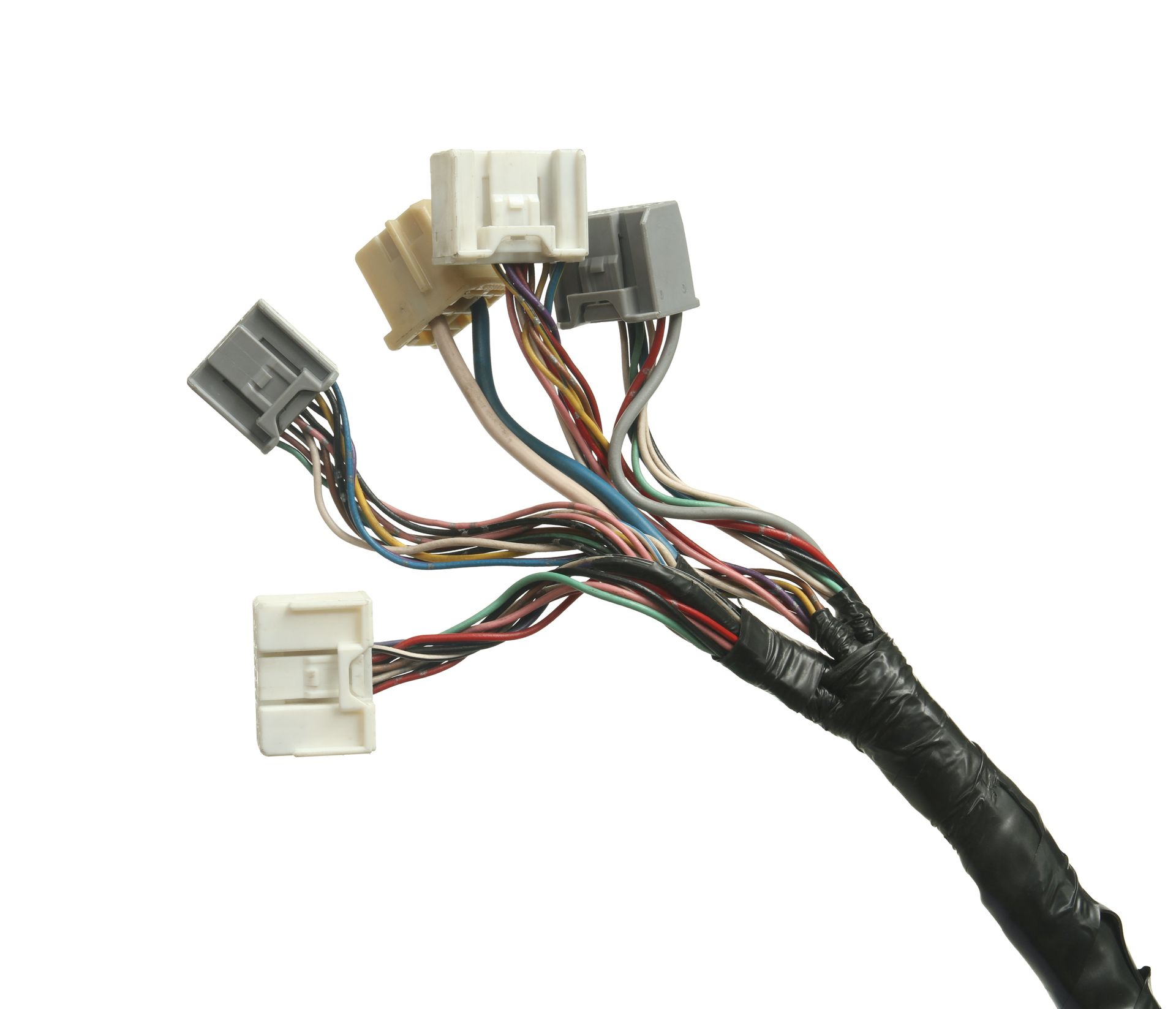

Custom Wire Harness Connectors: 5 Tips To Get Hooked Up Right

In terms of creating custom wire harnesses, choosing the proper connectors is crucial for ensuring a reliable and efficient electrical connection. Below, we will explore essential factors to consider when selecting and working with wire harness connectors. By following these guidelines, you can confidently create wire harnesses that meet your specific application requirements and deliver optimal performance.

Choose the Right Connector for the Application

Selecting the appropriate connector is the first step in creating a successful wire harness. Consider factors such as wire size, the number of wires to be connected, the environmental conditions in which the connector will be used, and cost. By understanding the unique needs of your application, you can choose connectors that provide a secure and durable connection while meeting your budgetary requirements.

Use the Correct Tools

Using the proper tools is essential for working with wire harness connectors effectively. Common tools include crimpers, pliers, and wire strippers. By utilizing the correct tools for each task, you can ensure precise and damage-free installations. This attention to detail will result in connectors that maintain their integrity and functionality over time.

Follow the Manufacturer's Instructions

Each manufacturer provides specific instructions for the installation and use of their wire harness connectors. Adhering to these instructions is vital for achieving reliable connections. Carefully read and follow the manufacturer's guidelines to guarantee proper installation, minimize the risk of damage, and optimize the performance of your wire harnesses.

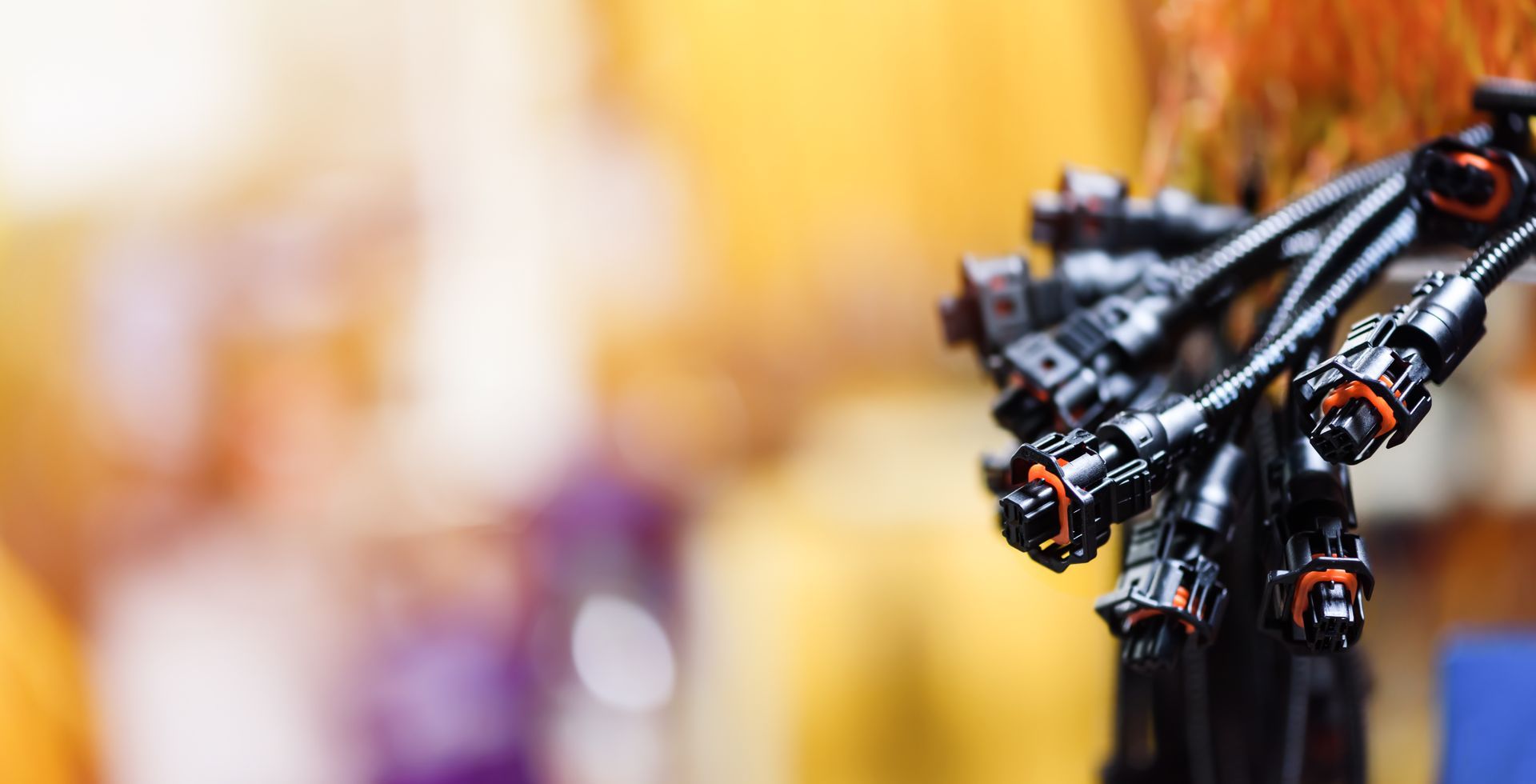

Inspect Connectors Before Use

Before incorporating connectors into your wire harness, it is crucial to inspect them for any signs of damage. Damaged connectors can compromise the overall integrity and reliability of the electrical connection. If you notice any damage or defects, it is imperative to replace the connectors before proceeding. Conducting thorough inspections ensures the quality and longevity of your wire harnesses.

Secure Connectors Properly

After the connectors are installed, securing them properly is essential to prevent accidental disconnections. Utilize methods such as tape, zip ties, or other appropriate fastening techniques to ensure connectors remain in place. This proactive approach safeguards against potential disruptions and guarantees the longevity of your wire harnesses.

Additional Tips:

- Maintain a clean work area to prevent contamination of connectors and ensure optimal performance.

- Keep connectors away from sharp objects that may cause damage during installation or operation.

- Use a lubricant specifically designed for connectors to facilitate smooth crimping and enhance overall ease of installation.

- After installation, test the connections to verify their functionality and reliability.

When creating custom wire harnesses, selecting and working with the right connectors is essential for achieving reliable and efficient electrical connections. By considering the application requirements, using the correct tools, following manufacturer's instructions, inspecting connectors for damage, and securely fastening them, you can ensure the success of your wire harnesses. Remember to maintain a clean workspace, protect connectors from potential harm, and test connections for proper functionality. By implementing these best practices, you can confidently create wire harnesses that deliver optimal performance and reliability for your specific needs.

Proudly Manufactured in the United States

At RPI, we take great pride in manufacturing custom wiring harnesses that are made right here in the US. From our base in Racine, Wisconsin, we use only the highest quality materials and components to craft wiring solutions that are durable, reliable, and built to last. By choosing RPI, you can trust that you are getting a product that is not only tailored to your specific needs, but also represents the quality and craftsmanship of American manufacturing.

Upload Your Design

Build Spec Review of your Design Guided by a Dedicated Program Manager

Design Review by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

Start Your Design

Design and Development Process with a Dedicated Program Manager

Design Drawings performed by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

More Recent Insights