Proper Cable Maintenance for Custom Wire Harness Applications: Ensuring Longevity and Reliability

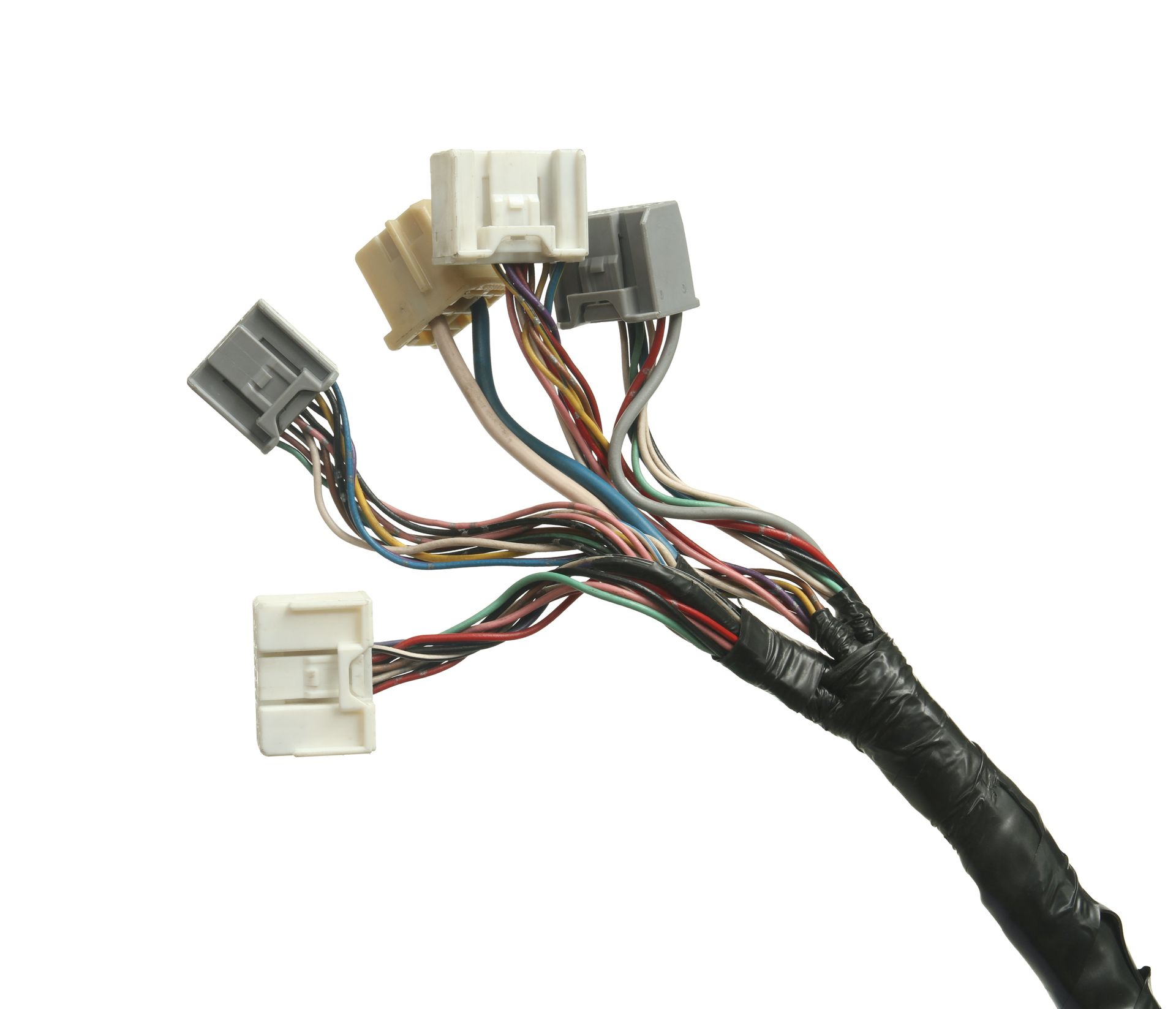

Cables play a vital role in various products, facilitating seamless communication between electrical components. To ensure their longevity and optimal functionality, proper cable maintenance is essential. By adhering to a few simple tips, you can keep your cables in excellent condition and prevent costly failures. RPI can guide you through the best practices for cable maintenance, covering areas such as developing a maintenance plan, regular inspections, repairs, proper storage, and additional measures to extend cable life.

Develop a Cable Maintenance Plan

Creating a comprehensive cable maintenance plan serves as the foundation for effective upkeep. Consider these following elements when developing your plan:

- Types of cables to be maintained

- Frequency of maintenance

- Specific tasks to be performed during maintenance

- Tools and equipment required

- Designating responsible personnel

Perform Regular Inspections

Regular inspections are crucial for identifying potential issues before they escalate into failures. During inspections, pay attention to the following:

- Damage to the insulation

- Loose or corroded connections

- Kinks or sharp bends

- Signs of wear and tear

Repair or Replace Damaged Cables

If you discover any damaged cables during inspections, it is imperative to address them promptly. While repairs can be challenging and time-consuming, it is often more effective to replace damaged cables to ensure optimal performance and reliability.

Store Cables Properly

Proper storage is essential for preventing cable damage when they are not in use. Adhere to the following guidelines when storing cables:

- Keep them in a cool, dry place

- Avoid direct exposure to sunlight

- Avoid stacking them too high

- Utilize cable wraps or protective coverings

Additional Measures to Extend Cable Life:

- Design cables with extra length: Providing a few extra feet of cable allows flexibility for repairs or adjustments without straining the connection points.

- Opt for high-quality cables: Investing in superior quality cables minimizes the risk of premature failures and ensures optimal performance.

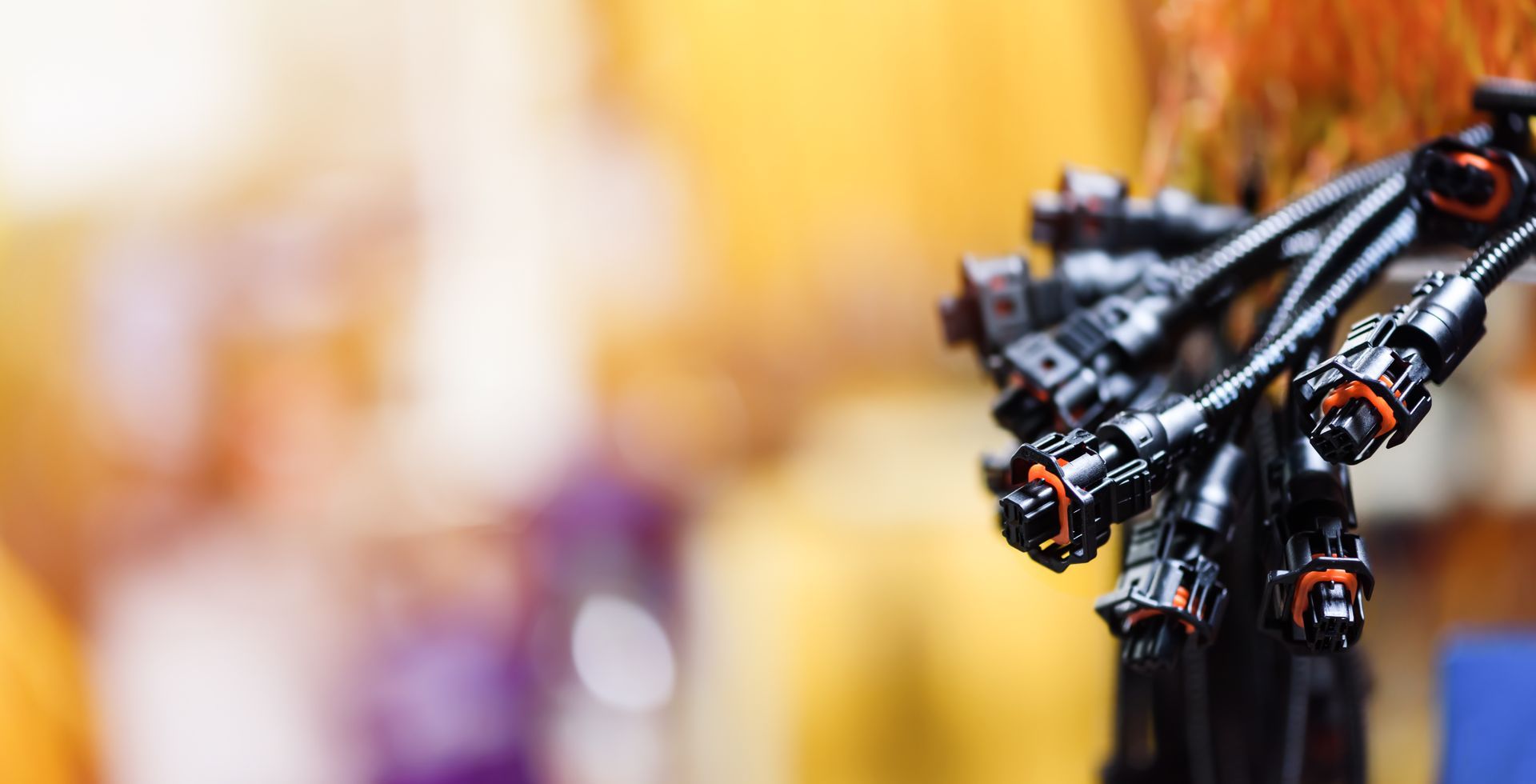

- Consider professional termination: Improper termination can lead to corrosion and other issues. Having your cables professionally terminated ensures clean and secure connections, reducing the chances of future problems.

Cleaning Connectors

Often overlooked, cleaning connectors is crucial for preventing signal loss and interference. Over time, connectors can accumulate dirt and corrosion. Use de-ionized water to clean connectors, ensuring optimal signal transmission.

Periodic Scheduled Re-Terminations

Periodically re-terminating cables is an effective maintenance practice to maintain clean and secure connections, preventing corrosion and related problems. Consider the following tips for re-termination:

- Use the correct tools, including a crimper, wire stripper, and heat gun.

- Prepare the cable by stripping the insulation from the ends.

- Crimp the connectors onto the wire ends.

- Shrink the heat shrink tubing over the connectors using a heat gun.

Additional Tips for Cable Maintenance:

- Label your cables for easy identification during repairs or adjustments.

- Use cable ties or restraints to keep cables organized and secure, protecting them from environmental factors.

- Avoid running cables across sharp objects or edges to prevent insulation damage.

- Ensure proper cable support to avoid strain or damage due to excess weight.

- Avoid overloading cables, as they have specific current-carrying capacities that, if exceeded, can lead to overheating and failure.

Proper cable maintenance is crucial for maximizing the lifespan and functionality of custom wire harnesses. By implementing a comprehensive maintenance plan, conducting regular inspections, addressing damages promptly, storing cables properly, and taking additional measures to extend cable life, you can prevent costly failures and ensure reliable connections.

By following these best practices and incorporating them into your cable maintenance routine, you can ensure that your custom wire harness applications operate smoothly and reliably for an extended period. Remember, cable maintenance is a proactive approach that saves time, effort, and resources in the long run by preventing unexpected failures and costly downtime.

If you have any questions or need further assistance with cable maintenance or selecting the right cables for your application, don't hesitate to reach out to RPI. We are here to provide expert guidance and support to help you maintain optimal performance and longevity for your wire harnesses.

Proudly Manufactured in the United States

At RPI, we take great pride in manufacturing custom wiring harnesses that are made right here in the US. From our base in Racine, Wisconsin, we use only the highest quality materials and components to craft wiring solutions that are durable, reliable, and built to last. By choosing RPI, you can trust that you are getting a product that is not only tailored to your specific needs, but also represents the quality and craftsmanship of American manufacturing.

Upload Your Design

Build Spec Review of your Design Guided by a Dedicated Program Manager

Design Review by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

Start Your Design

Design and Development Process with a Dedicated Program Manager

Design Drawings performed by a Dedicated Project Engineer

Build to Order Time Schedule

Proposed Budget Estimate based on quantity and Required Production

Get Started Now

More Recent Insights